Welcome back to part 2 of the Jay Bates Miter Saw Station build! In this installment, the first step was to level the base cabinets, which took a little longer than expected due to the slope of my garage floor. After leveling the cabinets, I mounted the work surface supports to the wall using two by two pieces screwed into the garage wall. The next step was to add the work surface on top of the base cabinets and supports, attaching it with screws. I also cut a hole for the dust collection port and attached the top cabinet carcasses to each other. Lastly, I added the drawer fronts and set up the fast cap best fence bench mount system. Overall, this project has been a great learning experience, and the Miter Saw Station has provided me with ample storage space in my workshop. I’m planning to add some Kaizen foam to the drawers to keep them organized, and I may also finish the drawer fronts for added durability. Thanks for watching this two-part series, and don’t forget to subscribe to our YouTube channel for more content every week!

This image is property of i.ytimg.com.

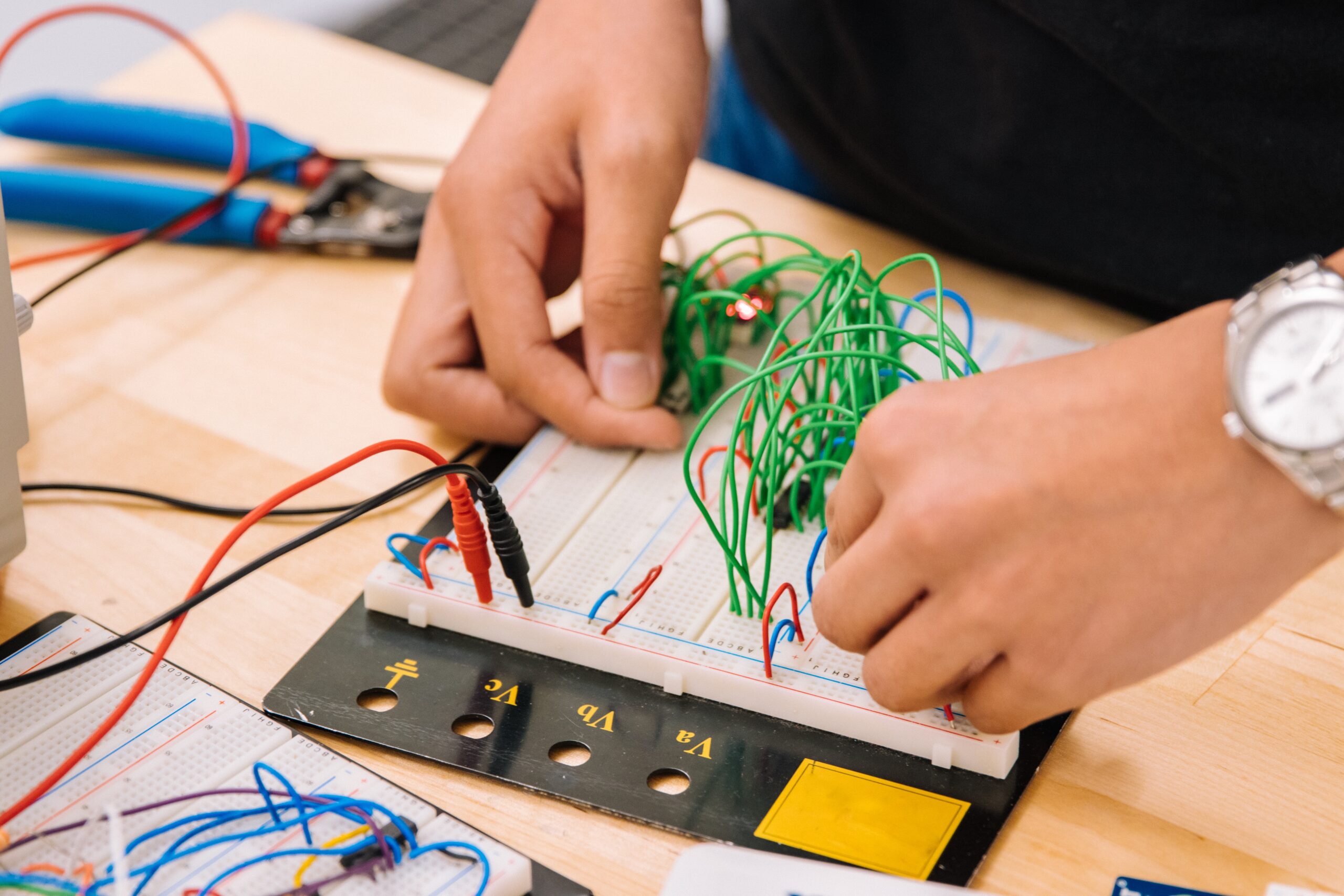

Leveling the Base Cabinets

Description of the problem with the garage floor slope

When setting up your miter saw station in your garage, one of the challenges you may face is dealing with an uneven garage floor. It’s common for garage floors to have a slight slope for drainage purposes, but this can cause issues when trying to level your base cabinets. If the cabinets are not leveled, it can affect the accuracy of your cuts and the overall stability of your miter saw station.

Process of leveling the base cabinets

To overcome the problem of an uneven garage floor, you will need to level your base cabinets. This can be done by adjusting the legs or using shims. Start by placing the cabinets in their desired position and use a level to determine which areas need adjustment. If the floor slope is minimal, you may be able to adjust the legs of the cabinets to achieve a level surface. If the slope is more pronounced, you may need to use shims to fill the gaps between the cabinets and the floor.

Difficulties encountered during the process

Leveling the base cabinets can be a tricky task, especially if you are working alone. It can be challenging to accurately measure and adjust the cabinets to ensure they are perfectly level. Additionally, if there are significant variations in the garage floor slope, it may require more time and effort to achieve a level surface. However, with patience and careful adjustment, you can successfully level your base cabinets and create a stable foundation for your miter saw station.

Mounting the Work Surface Supports

Materials used for the supports

To mount the work surface supports, you will need the following materials:

- 2×4 lumber or plywood cut to the desired length for the supports

- Lag screws or anchor screws for attaching the supports to the garage wall

- Power drill with appropriate drill bits

- Level for ensuring proper alignment

Method of attaching the supports to the garage wall

Start by determining the desired height and spacing for the work surface supports. Mark the locations on the garage wall where the supports will be attached. Use a power drill to create pilot holes in the wall at these marked locations. Then, attach the supports to the wall using lag screws or anchor screws. Make sure the supports are level and securely fastened to the wall to ensure stability.

Spacing and number of screws used

The spacing and number of screws used will depend on the size and weight of your work surface. As a general guideline, it is recommended to have a support every 2 to 3 feet along the length of the work surface. For smaller work surfaces, two supports may be sufficient, while larger surfaces may require additional supports for added stability. Use enough screws to securely fasten the supports to the wall, typically one or two screws per support.

Attaching the Work Surface

Steps for attaching the work surface to the cabinets

To attach the work surface to the cabinets, follow these steps:

- Place the work surface on top of the leveled base cabinets, ensuring it is centered and aligned properly.

- Use a pencil or marker to mark the locations where the work surface will be attached to the cabinets.

- Pre-drill pilot holes in the marked locations to prevent splitting the wood.

- Attach the work surface to the cabinets using screws. The size of the screws will depend on the thickness of the work surface and the type of material used.

- Make sure the work surface is securely fastened to the cabinets to prevent any movement or wobbling while working.

Type and size of screws used

The type and size of screws used for attaching the work surface to the cabinets will depend on the material and thickness of the work surface. For most wood-based work surfaces, wood screws are the recommended choice. The size of the screws should be appropriate for the thickness of the work surface and the type of material used. It is important to use screws that are long enough to penetrate both the work surface and the cabinet securely.

Ensuring flush alignment with the cabinets

To ensure a flush alignment between the work surface and the cabinets, it is crucial to carefully measure and align the work surface before attaching it. Double-check the positioning of the work surface on top of the cabinets and use a level to ensure it is perfectly aligned. This will help create a smooth and seamless transition between the work surface and the cabinets, providing a sturdy and functional miter saw station.

Cutting the Hole for Dust Collection Port

Using a self-feeding Forstner bit

To cut the hole for the dust collection port in your work surface, you can use a self-feeding Forstner bit. This type of drill bit is designed to create precise, clean holes in wood. It features a center point and cutting edges that enable it to bore clean, accurate holes without splintering or tear-out.

Finishing the hole with a jigsaw

After using the Forstner bit to create the initial hole for the dust collection port, you may need to finish the hole to the desired size and shape using a jigsaw. A jigsaw allows for more flexibility and control in shaping the hole to accommodate the dust collection port.

Challenges faced while using a jigsaw

Using a jigsaw to finish the hole for the dust collection port can present some challenges. It requires steady hands and precise control to cut along the marked outline and create a clean, accurate hole. The jigsaw blade may also need to be changed depending on the thickness and type of material being cut. It is important to practice proper technique and take your time to ensure a smooth and precise cut when using a jigsaw for this task.

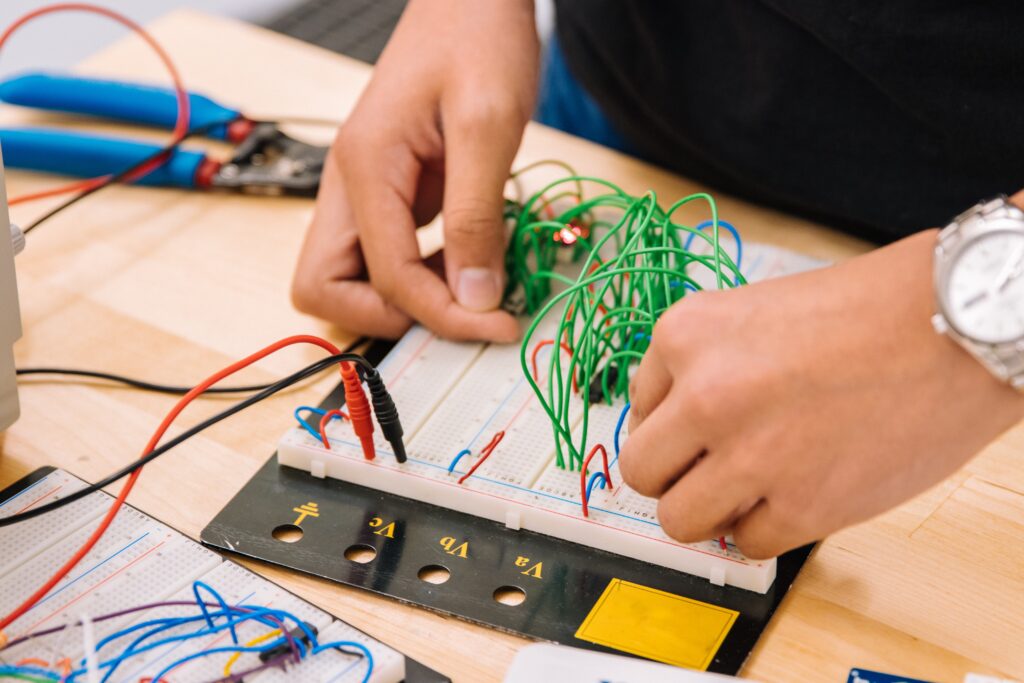

This image is property of images.unsplash.com.

Connecting the Top Cabinet Carcasses

Description of the top cabinet carcasses

The top cabinet carcasses are the uppermost part of your miter saw station. They typically consist of a frame constructed from 2×4 lumber or plywood and provide additional storage space for tools and accessories. These carcasses are designed to be attached to each other and the work surface to create a cohesive and functional unit.

Method of connecting them to each other

To connect the top cabinet carcasses to each other, you can use pocket hole joinery. Pocket hole joinery involves creating angled holes, or pockets, in the wood and using specialized screws to join the pieces together. This method provides strong and durable connections while minimizing the visibility of screws on the exterior surface.

Number and type of screws used

The number of screws used will depend on the size and weight of your top cabinet carcasses. As a general guideline, it is recommended to use at least two screws for each connection point. The type of screws used for pocket hole joinery are typically self-tapping, coarse-threaded screws specifically designed for this method. These screws provide excellent holding power and are available in various lengths to accommodate different material thicknesses.

Attaching the Side Wings for Dust Collection

Explanation of the purpose of side wings

Side wings are extensions that are attached to the sides of the miter saw station to provide additional support and dust collection capabilities. They help to create a larger work surface area and improve the efficiency of the dust collection system by capturing more of the airborne dust and debris generated during cutting.

Method of attaching them using pocket hole screws

To attach the side wings to the miter saw station, you can once again utilize pocket hole joinery. Create angled holes, or pockets, in the side wings and corresponding holes in the main structure of the miter saw station. Then, use pocket hole screws to secure the side wings in place. This method ensures a strong and stable connection while minimizing the visibility of screws on the exterior surface.

Importance of dust collection in a miter saw station

Dust collection is critical in a miter saw station for several reasons. First and foremost, it helps maintain a clean and safe working environment by reducing the amount of airborne dust and debris. This is important for your health and also helps prolong the life of your tools and equipment. Second, proper dust collection can improve the accuracy and quality of your cuts by minimizing the accumulation of sawdust around the cutting area. Lastly, effective dust collection contributes to overall workshop efficiency and productivity.

This image is property of images.unsplash.com.

Adding the Top Support Pieces

Description of the top support pieces

The top support pieces are horizontal beams or boards that provide additional stability and strength to the miter saw station. They are typically attached to the top cabinet carcasses and the side wings, creating a solid framework for the entire structure.

Procedure for attaching them using pocket holes

To attach the top support pieces, follow these steps:

- Measure and cut the top support pieces to the desired length.

- Create pocket holes in the top support pieces using a pocket hole jig and drill.

- Position the top support pieces on top of the cabinet carcasses and side wings, aligning them with the pocket hole locations.

- Use pocket hole screws to secure the top support pieces in place, making sure they are level and flush with the surrounding surfaces.

- Double-check the stability and strength of the miter saw station, ensuring the top support pieces are firmly attached and provide adequate support.

Ensuring stability and strength of the miter saw station

The stability and strength of your miter saw station are crucial for safe and accurate woodworking. To ensure a sturdy structure, it is important to properly attach the top support pieces using pocket hole joinery, as described above. Additionally, regularly inspect the connections and make any necessary adjustments or reinforcements to maintain the stability and strength of the station.

Attaching the Fence Backing Pieces

Materials required for the fence backing pieces

To attach the fence backing pieces, you will need the following materials:

- 1×4 lumber or plywood cut to the desired length for the backing pieces

- Screws appropriate for the thickness of the backing pieces and the material of the fence

Process of attaching them to the miter saw station

To attach the fence backing pieces, follow these steps:

- Measure and cut the backing pieces to the desired length.

- Position the backing pieces on the backside of the miter saw station fence, ensuring they are aligned with the edges and flush with the top surface.

- Pre-drill pilot holes in the backing pieces to prevent splitting.

- Securely attach the backing pieces to the fence using screws, ensuring they are evenly spaced and provide adequate support.

Number of screws and type used

The number of screws used will depend on the length and weight of the fence backing pieces. As a general guideline, it is recommended to use at least two screws for each backing piece. The type of screws used will depend on the thickness and material of the backing pieces and the miter saw fence. Make sure to choose screws that are long enough to penetrate both the backing pieces and the fence securely.

This image is property of images.unsplash.com.

Building the Top Cubby System

Detailed explanation of the top cubby system

The top cubby system is an additional storage feature that can be built on top of the miter saw station. It typically consists of cubbyholes or shelves that provide convenient storage for small tools, accessories, and other workshop items. The top cubby system helps keep your workspace organized and maximizes the utilization of vertical space in your garage.

Method of construction using corner clamps

To build the top cubby system, you can use corner clamps to hold the pieces together during assembly. Start by cutting the cubbyhole dividers and shelves to the desired size. Then, position the pieces in the desired configuration and use corner clamps to hold them in place. This will ensure accurate alignment and provide stability while attaching the pieces together with screws or other suitable fasteners.

Tools and materials required

To build the top cubby system, you will need the following tools and materials:

- 1×4 or 1×6 lumber for the cubbyhole dividers and shelves

- Corner clamps for assembly

- Screws for fastening the pieces together

- Power drill with appropriate drill bits

- Measuring tape and pencil for marking the dimensions

Conclusion

Summary of the miter saw station build process

Building a miter saw station in your garage can greatly enhance your woodworking experience. By following the steps outlined in this article, you should be well on your way to creating a sturdy and functional miter saw station. From leveling the base cabinets and mounting the work surface supports to attaching the work surface and building additional features like the top cabinet carcasses and top cubby system, each step plays a crucial role in creating a high-quality workspace.

Importance of the project in providing storage space

One of the primary benefits of a miter saw station is the ample storage space it provides. With the addition of base cabinets, top cabinet carcasses, side wings, and the top cubby system, you can effectively organize and store your tools, accessories, and other workshop items. This not only promotes a clean and clutter-free working environment but also improves workflow efficiency and productivity.

Plans for future improvements

Once your miter saw station is complete, you can continuously assess and improve its functionality to meet your evolving needs. Consider incorporating additional features such as integrated dust collection systems, lighting solutions, or customized workholding options. Regularly maintain and upgrade your miter saw station to ensure optimal performance and a workspace that truly supports your woodworking projects.