Well, I haven't been posting metal projects lately though I have been working on some unfinished projects that have been posted before but progress is kinda really slow due to other pressing projects that needed to be done as soon as possible. So much work to be done here in the property since we have been experiencing continuous rains with some strong winds similar to HABAGAT, that the ground has been soaked with water for a long time that the soil have soften. Fallen leaves and tree branches have been scattered around and even some trees have been uprooted or fell by itself due to softened soil surroundings and have to do some cutting and clearing and other maintenance work all around.

Here are what I have been doing this past few weeks or months.And some are still on going !!

PROJECT:

Replace two busted fluorescent lights on the driveway:

The pipe scaffoldings and several pipe braces I fabricated in year 2009. Just want to share this old project of GI pipes of 5 feet in height each and when assembled, total height is 15 feet without the caster wheels.

These are the 8 pipe pins with welded metal rings in the middle to connect each piece of the scaffolding.

These are the four casters attached to a removable tubings which I didn't use due to un-evenness of the sloping concrete driveway.

CIGWELD Weldskill 250 amp Mig Welder

AHP Alpha-TIG 200X welder

HITRONIC 300 Amp DC Inverter IGBT Welder

YAMATO 300 amp AC Stick Welder

YAMATO 200 amp DC Inverter IGBT Welder

DeWALT Chopsaw

HOBART and ESAB Welding Helmets

cloned STIHLs

MS 044 chainsaw

MS 070 chainsaw

Re: What's making me Busy lately ???

Scaffoldings have been set up so I can replace the two busted fluorescent lights on a more than 20 feet of lamp post.

Two different angles as the lights were turned on, and let there be lights again !!! :clap:

CIGWELD Weldskill 250 amp Mig Welder

AHP Alpha-TIG 200X welder

HITRONIC 300 Amp DC Inverter IGBT Welder

YAMATO 300 amp AC Stick Welder

YAMATO 200 amp DC Inverter IGBT Welder

DeWALT Chopsaw

HOBART and ESAB Welding Helmets

cloned STIHLs

MS 044 chainsaw

MS 070 chainsaw

Re: What's making me Busy lately ???

PROJECT:

Small metal/iron ramp for my Wheel Barrow:

Made this metal project since the wooden ramp I have been using has been eaten up by termites and became un functional.

This very simple ramp project was finished with full welds using the YAMATO 200amp DC Inverter. I did not bother to do a WIP anymore and just proceeded with the project. Cutting my metals/steel of 16mm and 12mm corrugated steel bars with two pieces of 2 X 2 angle bars also welded on the sides as you see in the pics. After cutting all the metals, I started positioning each joint and tack welded with 6013 rods and after all have been tacked welded, made full welds using 7018 and 7024, playing simply with these two rods. Enjoyed it so much welding these thick metals, for I know there will never be a problem of burn through. You will just see how the welds dig deep onto the metal making good metal fusion.

So who says this YAMATO welder can't do full welding continuously or this is only good for spot welding ? I think you are wrong guys or maybe you are saying that 'coz you simply do not know how to use a welder properly or correctly and not understanding its duty cycle properly. Sorry to say this guys but this welder may seem for light duty but for sure it does deliver.

CIGWELD Weldskill 250 amp Mig Welder

AHP Alpha-TIG 200X welder

HITRONIC 300 Amp DC Inverter IGBT Welder

YAMATO 300 amp AC Stick Welder

YAMATO 200 amp DC Inverter IGBT Welder

DeWALT Chopsaw

HOBART and ESAB Welding Helmets

cloned STIHLs

MS 044 chainsaw

MS 070 chainsaw

Re: What's making me Busy lately ???

Finished the metal project with four coats of metal epoxy primer.

This is how this ramp will be utilized.

A view from the lower portion as the wheel barrow goes down.

A view from the top portion as the wheel barrow goes up.

CIGWELD Weldskill 250 amp Mig Welder

AHP Alpha-TIG 200X welder

HITRONIC 300 Amp DC Inverter IGBT Welder

YAMATO 300 amp AC Stick Welder

YAMATO 200 amp DC Inverter IGBT Welder

DeWALT Chopsaw

HOBART and ESAB Welding Helmets

cloned STIHLs

MS 044 chainsaw

MS 070 chainsaw

Re: What's making me Busy lately ???

Due to this eventuality of some large ipil ipil trees have fallen, I am doing a must metal project again to aide me during my task ahead.

CIGWELD Weldskill 250 amp Mig Welder

AHP Alpha-TIG 200X welder

HITRONIC 300 Amp DC Inverter IGBT Welder

YAMATO 300 amp AC Stick Welder

YAMATO 200 amp DC Inverter IGBT Welder

DeWALT Chopsaw

HOBART and ESAB Welding Helmets

cloned STIHLs

MS 044 chainsaw

MS 070 chainsaw

Re: What's making me Busy lately ???

PROJECT:

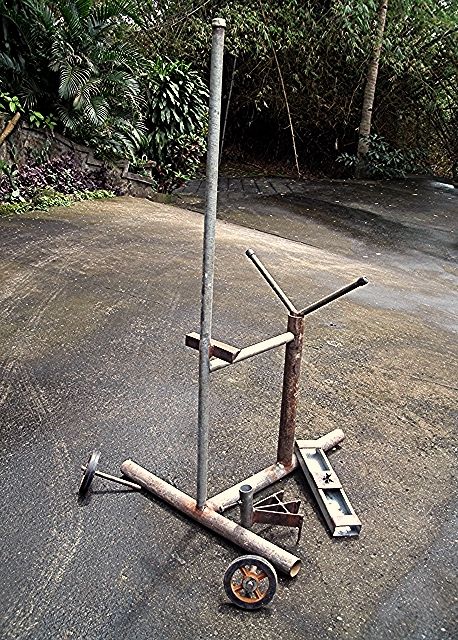

A Power saw and a Log stand:

This is an on going metal project using 2" GI pipes as its main frame with some 1"and 1/2" GI pipes and wheels and other attachments.

The basic construction of the stand

The two 6" rubber wheels with their axles

The power saw holster or casing that will be welded on the main body frame.

CIGWELD Weldskill 250 amp Mig Welder

AHP Alpha-TIG 200X welder

HITRONIC 300 Amp DC Inverter IGBT Welder

YAMATO 300 amp AC Stick Welder

YAMATO 200 amp DC Inverter IGBT Welder

DeWALT Chopsaw

HOBART and ESAB Welding Helmets

cloned STIHLs

MS 044 chainsaw

MS 070 chainsaw

Re: What's making me Busy lately ???

The metal claws constructions that is adjustable up and down to hold the log that will be sawed.

The full welded plates of the metal claws

CIGWELD Weldskill 250 amp Mig Welder

AHP Alpha-TIG 200X welder

HITRONIC 300 Amp DC Inverter IGBT Welder

YAMATO 300 amp AC Stick Welder

YAMATO 200 amp DC Inverter IGBT Welder

DeWALT Chopsaw

HOBART and ESAB Welding Helmets

cloned STIHLs

MS 044 chainsaw

MS 070 chainsaw

Re: What's making me Busy lately ???

How this metal claws will be utilized? it will be positioned and installed in the 1" pipe, adjustable in different heights that will hold the log firmly while it is being sawed in a certain specified length.

This bolt will be tightened as the log sits on the welded angle iron. A circular wheel will still be fabricated and welded on to the head of the bolt for easier turning.

CIGWELD Weldskill 250 amp Mig Welder

AHP Alpha-TIG 200X welder

HITRONIC 300 Amp DC Inverter IGBT Welder

YAMATO 300 amp AC Stick Welder

YAMATO 200 amp DC Inverter IGBT Welder

DeWALT Chopsaw

HOBART and ESAB Welding Helmets

cloned STIHLs

MS 044 chainsaw

MS 070 chainsaw

Re: What's making me Busy lately ???

This is how that holster will appear with the power saw inside.

Full weld application of this 1/8" plate onto the scrap of 2.0 mm thick galvanized light metal framing stud sourced from a junk shop.

The locking bolt that will gtip the guide bar into place. A circular wheel will again be fabricated and welded on the bolts' head for easy turning.

CIGWELD Weldskill 250 amp Mig Welder

AHP Alpha-TIG 200X welder

HITRONIC 300 Amp DC Inverter IGBT Welder

YAMATO 300 amp AC Stick Welder

YAMATO 200 amp DC Inverter IGBT Welder

DeWALT Chopsaw

HOBART and ESAB Welding Helmets

cloned STIHLs

MS 044 chainsaw

MS 070 chainsaw

Re: What's making me Busy lately ???

This is how this holster will positioned and welded to the main frame.

More attachments will still be welded on this stand, this is an on going metal project being done with the YAMATO welder. A handle will be welded for easy handling andto be rolled to the job site and a foldable support welded at the end part of the 2" GI pipe for more stability. My next post will be when everything is completed, cleaned, painted and in action.

Thanks for viewing this project and to be continued !! 😉

CIGWELD Weldskill 250 amp Mig Welder

AHP Alpha-TIG 200X welder

HITRONIC 300 Amp DC Inverter IGBT Welder

YAMATO 300 amp AC Stick Welder

YAMATO 200 amp DC Inverter IGBT Welder

DeWALT Chopsaw

HOBART and ESAB Welding Helmets

cloned STIHLs

MS 044 chainsaw

MS 070 chainsaw

Re: What's making me Busy lately ???

I'm still trying to figure out what you're doing, Rosy. Is it a log cutting jig plus transporter?

BTW, what are you going to do with that ipil-ipil log? If you're just going to make firewood out of it, baka maka-arbor ako ng konti. Have not worked on ipil-ipil yet. may be good experience.

Been doing a lot of welding making some complex clamps for the strip planks on my boat. Tried welding some nuts like you did. Natunaw!

Any tips?

Re: What's making me Busy lately ???

I'm still trying to figure out what you're doing, Rosy. Is it a log cutting jig plus transporter?

plus chainsaw holder sir ding..:)

Re: What's making me Busy lately ???

@ balarila ( Ding ),

Actually Ding, its more of a log cutting stand ( sort of a jig if you may call it )where I can put/fix lengthy thick diameter branches on it for easy cross cutting instead of cutting them on the ground. That's putting some stress on my back. We use them for (fuel) fire wood sa dirty kitchen.

With regards to the main trunk, maybe I will cut it to certain lengths of 6',8',10' or 12' or depends on the total length of the main trunk and my plan, then will slice them up into planks again to 1 1/2" or 2" thick and then will stack them in the garage to air dry for a year or two.

For your nut welding, practice with applying tack welds on a scrap metal and when doing so, hinde masyadong naka babad yung rod sa wine-welding na material. You will soon get it right. 😉

CIGWELD Weldskill 250 amp Mig Welder

AHP Alpha-TIG 200X welder

HITRONIC 300 Amp DC Inverter IGBT Welder

YAMATO 300 amp AC Stick Welder

YAMATO 200 amp DC Inverter IGBT Welder

DeWALT Chopsaw

HOBART and ESAB Welding Helmets

cloned STIHLs

MS 044 chainsaw

MS 070 chainsaw

Re: What's making me Busy lately ???

For your nut welding, practice with applying tack welds on a scrap metal and when doing so, hinde masyadong naka babad yung rod sa wine-welding na material. You will soon get it right. 😉

Hit/miss. Kalahati tunaw, kalahati dikit.

Tiyagaan lang talaga. And lots of spare nuts!

Pero meron namang JBWeld. Pwede na rin.

Re: What's making me Busy lately ???

Yes Ding, tyagaan lang talaga ang kailangan, and knowing several techniques in applying weld beads.

Cannot say anything about the JB Weld, haven't used one yet. But if you have one then try using it, might work for you. 😉 :p

CIGWELD Weldskill 250 amp Mig Welder

AHP Alpha-TIG 200X welder

HITRONIC 300 Amp DC Inverter IGBT Welder

YAMATO 300 amp AC Stick Welder

YAMATO 200 amp DC Inverter IGBT Welder

DeWALT Chopsaw

HOBART and ESAB Welding Helmets

cloned STIHLs

MS 044 chainsaw

MS 070 chainsaw