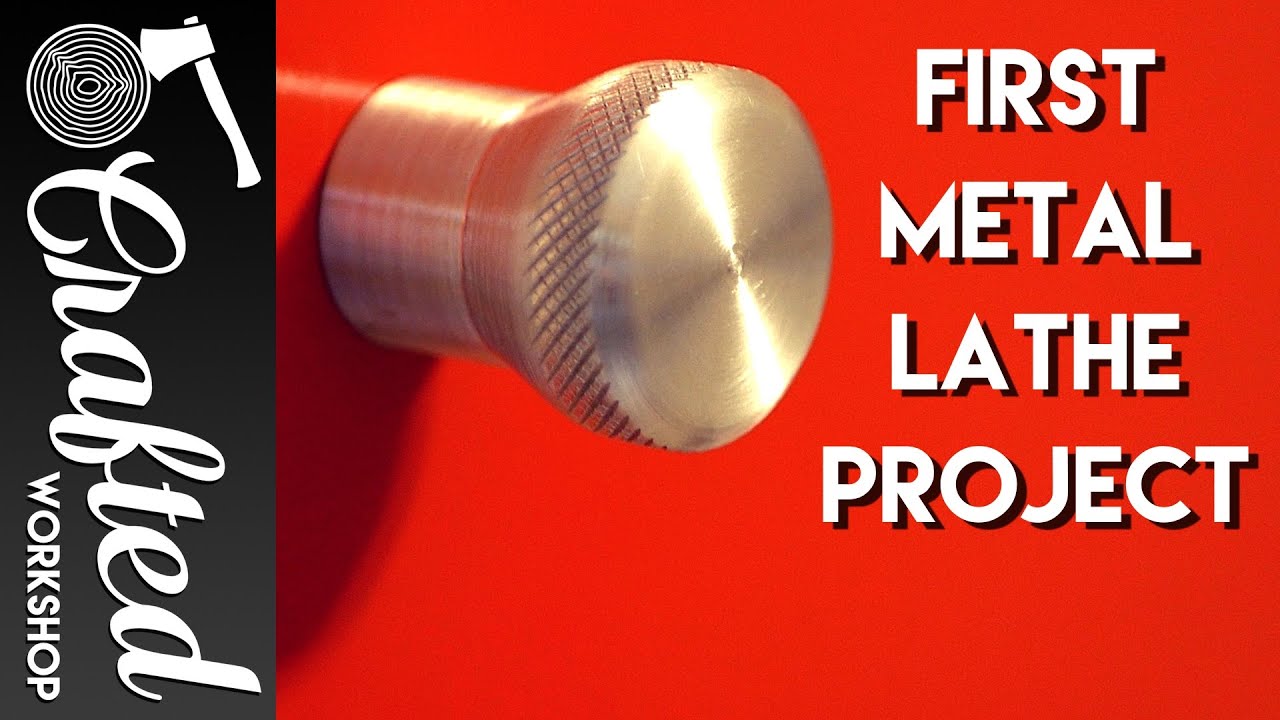

Hey there! In this article, we’ll be exploring the process of turning an aluminum knob on a metal lathe. This is a video tutorial by Crafted Workshop, where Johnny Brook takes you through the steps of creating a knob using a metal lathe. He starts off by explaining the basics of using a metal lathe, including how to control your tool using knobs and levers. Then, he demonstrates the process of cutting a piece of aluminum rod using a cut-off tool, taking care to align the tip of the blade with the center of the rod. Johnny emphasizes the importance of safety, wearing protective glasses, and ensuring the chuck is snug before starting the lathe. He then shows how to change the tooling and perform facing, chamfering, knurling, and sanding to achieve a smooth and finished surface. Finally, he guides you through the steps of drilling and tapping a hole in the knob to allow for attachment. If you’re interested in metalworking or machining, this video is perfect for you. So let’s dive in and learn how to turn an aluminum knob on a metal lathe!

This image is property of i.ytimg.com.

Preparing the Stock

Before starting the metal lathe project, you’ll need to choose the right material for the knob. In this case, the recommended choice is aluminum because it is soft and easy to work with. Specifically, aluminum 6061 is a popular choice for lathework. You can easily purchase a 24-inch piece of aluminum 6061 from online retailers like Amazon for a reasonable price.

Once you have the aluminum stock, the first step is to cut a piece off of it using a cut-off tool. This tool is essentially a small blade that you align with the center of the aluminum rod. To do this, line up the dead center in the tailstock and the tip of the blade. When making the cut, it’s best to do it close to the chuck to leave as much workpiece as possible. It’s important to note that when working with aluminum, it’s recommended to use WD-40 as a lubricant to reduce heat generation. Also, don’t forget to wear safety glasses when using the lathe as it can be a dangerous tool if not used properly.

Setting up the Metal Lathe

Once you have the aluminum stock cut to size, it’s time to set up the metal lathe. The first step in setting up the metal lathe is adjusting the chuck. Make sure the chuck is nice and snug before proceeding. Next, you’ll need to align the dead center and the blade. This can be done by aligning the tip of the blade with the center of the aluminum stock. It’s a simple process that ensures the blade is positioned correctly for cutting.

After aligning the dead center and the blade, it’s important to set the RPM (revolutions per minute) of the lathe. For facing the workpiece and other cutting operations, it’s recommended to set the RPM fairly low to keep the heat down. The exact RPM will depend on the specific lathe you are using, so be sure to consult the lathe’s manual for the appropriate settings.

Facing the Workpiece

Now that the metal lathe is set up, it’s time to start working on the aluminum knob. The first step in shaping the knob is to face the workpiece. Facing the workpiece involves removing a small amount of material from the face and sides of the aluminum stock to create a flat and clean surface to work with. To do this, you will use a right-facing cutting tool. Set the amount of material you want to remove and adjust the RPM accordingly. It’s recommended to start with a low RPM and gradually increase as needed.

Using the right-facing cutting tool, carefully remove material from the face and sides of the aluminum stock. Take your time and go slow to ensure a smooth and precise cut. This process will leave you with a clean and flat surface on the aluminum stock.

Chamfering the Edge

After facing the workpiece, the next step is to chamfer the edge of the aluminum knob. Chamfering involves creating a beveled edge on the outside edge of the knob to give it a finished look. To do this, you’ll need a 45-degree angle cutting tool. This tool has 45-degree angle cutters on either side, which will create a nice chamfer on the edge of the knob.

Using the 45-degree angle cutting tool, carefully remove material from the edge of the aluminum knob. Take your time and go slow to achieve a clean and precise chamfer. This step will give the knob a professional and polished appearance.

This image is property of images.unsplash.com.

Knurling

Knurling is a decorative technique that adds texture and grip to the surface of the knob. To knurl the knob, you’ll need to turn down the speed of the lathe to around 200-300 RPM. This slower speed allows for better control during the knurling process. Additionally, using WD-40 as a lubricant will help reduce friction and improve the knurling results.

To knurl the knob, use two knurling wheels. Apply gentle pressure as you roll the wheels along the surface of the knob. The knurling wheels will create the desired pattern and texture. Take your time and ensure even pressure for consistent results. Once the knurling is complete, you’ll have a textured surface that not only looks great but also provides a comfortable grip.

Sanding and Finishing

After knurling the knob, it’s time to move on to sanding and finishing. Start by using 80 grit sandpaper to remove any roughness or imperfections on the surface of the knob. Gradually work your way up to finer grits, such as 120, 220, and finally 320, to achieve a smooth and polished finish. Each sanding grit will help refine the surface of the knob and remove any scratches left by the previous grit.

As you sand, be sure to apply even pressure and move in a circular motion to ensure an even finish. Keep checking the surface to make sure you’re achieving the desired smoothness. Once you’ve reached the final grit, you’ll have a beautifully finished knob ready for the next step.

This image is property of images.unsplash.com.

Parting off the Piece

To separate the knob from the remaining stock, you’ll need to use a parting or cutoff tool. This tool is specifically designed to make clean and precise cuts when parting off a workpiece. Before using the parting tool, reduce the speed of the lathe to around 250 RPM. This lower speed allows for better control during the cutting process.

With the lathe at the appropriate speed, carefully guide the parting or cutoff tool into the stock, making a clean cut to separate the knob. Remember to go slow and maintain a consistent pace to prevent the stock from shattering or overheating. Once the cut is complete, you’ll have the knob separated and ready for the next step.

Drilling and Tapping a Hole

If you want to attach the knob to a cabinet or any other surface, you’ll need to drill and tap a hole in the end of the knob. For drilling and tapping, it’s recommended to use a drill press for accuracy. While it is possible to drill and tap on the lathe, it can be more challenging and less precise, especially when working with small workpieces like a knob.

Begin by drilling a hole of the appropriate diameter using a drill bit. The hole should be slightly smaller than the diameter of the bolt or screw you’ll be using to attach the knob. Once the hole is drilled, use a tap to create the threads inside the hole. A tap is a cutting tool that will carve the threads into the hole, allowing for a secure and tight fit with the bolt or screw.

While tapping, be sure to keep the tap as vertical as possible to ensure straight and even threads. You can use compressed air to clean out the hole and tap during the process. Once the tap has gone to full depth, run it through the hole a couple more times to clean up and smoothen the threads. Lastly, use a countersink to remove any burrs or rough edges around the hole, ensuring a clean and professional finish.

This image is property of images.unsplash.com.

Removing the Burr

After tapping the hole, there may be a burr or rough edge around the opening. To remove it, use a countersink bit or tool. The countersink will smooth out the edge of the hole and remove any imperfections, making it easier to insert the bolt or screw.

Place the countersink bit in a drill or drill press and gently run it along the edge of the hole, applying light pressure. This will remove the burr and create a clean chamfer around the opening. Be careful not to apply too much pressure or go too deep, as it may affect the fit of the bolt or screw. Once the burr is removed, you’ll have a perfectly finished hole ready for attaching the knob.

Conclusion

Congratulations! You’ve successfully turned an aluminum knob on a metal lathe. Throughout the process, you’ve learned various techniques such as facing the workpiece, chamfering the edge, knurling, sanding and finishing, parting off the piece, drilling and tapping a hole, and removing the burr. Each step contributes to creating a high-quality and professional-looking knob that can be used for various applications.

Remember, working with a metal lathe requires patience, precision, and attention to detail. Always prioritize safety by wearing safety glasses and following proper lathe operating procedures. If you’re new to metalworking or machining, don’t worry, it takes time to develop the necessary skills and muscle memory. Practice and repetition will help you improve and achieve better results.

Whether you’re interested in metalworking or woodworking, having a metal lathe opens up a whole new world of possibilities. If you don’t have access to a metal lathe, consider checking locally for resources like maker spaces or retired machinists who may be willing to share their expertise. Metalworking can be a rewarding and fulfilling hobby or profession, so don’t hesitate to start exploring this fascinating craft.

Thank you for joining us on this journey to learn how to turn an aluminum knob on a metal lathe. If you enjoyed this video and are interested in more project videos, be sure to subscribe to Crafted Workshop on YouTube. Also, check out their second channel for additional content and consider supporting them on Patreon for exclusive benefits and giveaways. Happy building!